Asset Oil Diagnostics

Optimise Maintenance intervals with Live Tank Oil Sampling (LTOS)

Live Tank Oil Sampling (LTOS) is a unique and cost-effective technique for sampling switchgear units, offering significant benefits in minimising switching requirements.

Proven to cut costs, minimise disruption and improve reliability

Conventional switchgear maintenance, based on regularly shutting down equipment for inspections, can reduce reliability, increase health and safety risks and cause unnecessary downtime and disruption.

Yet research proves that the clear majority of these units would operate safely and reliably for many years, without any additional maintenance.

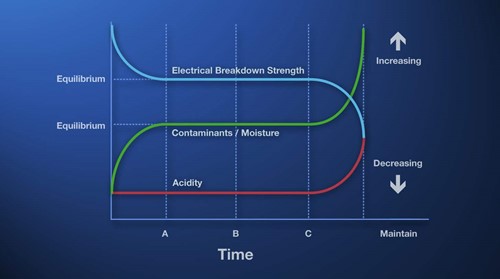

Figure 1 Schematic representation of oil condition parameters as a function of time (for oil-filled switchgear)

Maintaining oil-filled 11kV switchgear using a time-based schedule can result in considerable wastage, as not all the equipment will require maintenance.

In fact, EA Technology research shows that in a typical switchgear population, over 90% will be operating normally and require no maintenance. Live Tank Oil Sampling allows customers to identify which assets require attention and which are operating normally. This allows them to take remedial action with the minimal of disruption to switchgear operations.

Key benefits of adopting an LTOS programme:

- Saves money by eliminating wasteful, time-based maintenance

- Minimises disruption to the network in a cost-effective way by obtaining samples while part of the unit remains live

- Measures oil condition accurately, indicating if maintenance is required

- Safely extends periods between maintenance interventions

- Warns of switchgear degradation before it leads to failure

- Increases asset reliability while also reducing costs

Techniques used for Live Tank Oil Sampling

By using oil quality and filtration techniques, it is possible to understand the internal condition of the units and accurately determine whether invasive maintenance is required.

Oil Quality

| Moisture | IEC60814 |

| Acidity | IEC 62021 |

| Breakdown Voltage Strength | IEC 60156 |

The oil quality technique measures moisture, acidity, and electrical breakdown strength. These parameters are primarily intended to give information on the condition of the oil, although indirectly they also provide some information on the condition of the switchgear unit.

Filtration & Solid Contamination Assessment

The oil is filtered through a filter paper using a vacuum pump to draw the oil through. The contamination and residue is collected on the filter paper which is then dried and analysed under the optical/scanning electron (SEM) microscopes to identify the particulate. Typical particulate include fibres, debris, insects, metallic materials, paint flakes and insulation materials. This test allows a deep understanding of the degradation of the oil and internal components.

Easy to interpret results

The results are provided in an easy-to-interpret ‘traffic light’ summary. After the oil analysis is completed at the EA Technology Oil Diagnostics Facility, the asset is given one of four ratings: Pass, Retest, Maintain, Action.

PASS:

Satisfactory oil condition, which enables an extended maintenance interval to be adopted and the unit should be re-sampled in five years.

RETEST:

Evidence of some oil degradation, the unit should be retested in 30-36 months (half PF interval for oil degradation).

MAINTAIN:

Indicates very poor oil quality, unit should be maintained within 6 months.

ACTION:

Extremely poor oil quality indicating the unit is prone to a catastrophic failure in the short term and the client will be advised accordingly.

With typically over 90% of assets gaining a pass grade, it is clear that Live Tank Oil Sampling can result in a significant reduction in unnecessary inspections and maintenance. This can result in substantial savings on maintenance budgets.

Download our Oil Diagnostics Data Sheet Switchgear below

Get in touch

Thank you for your interest in EA Technology. You can request information or a free callback by clicking the link below. One of our experts will be in touch with you shortly.