Case Study: Partial Discharge Survey For HV Assets

-

19 September 2019

-

Brad Monaghan

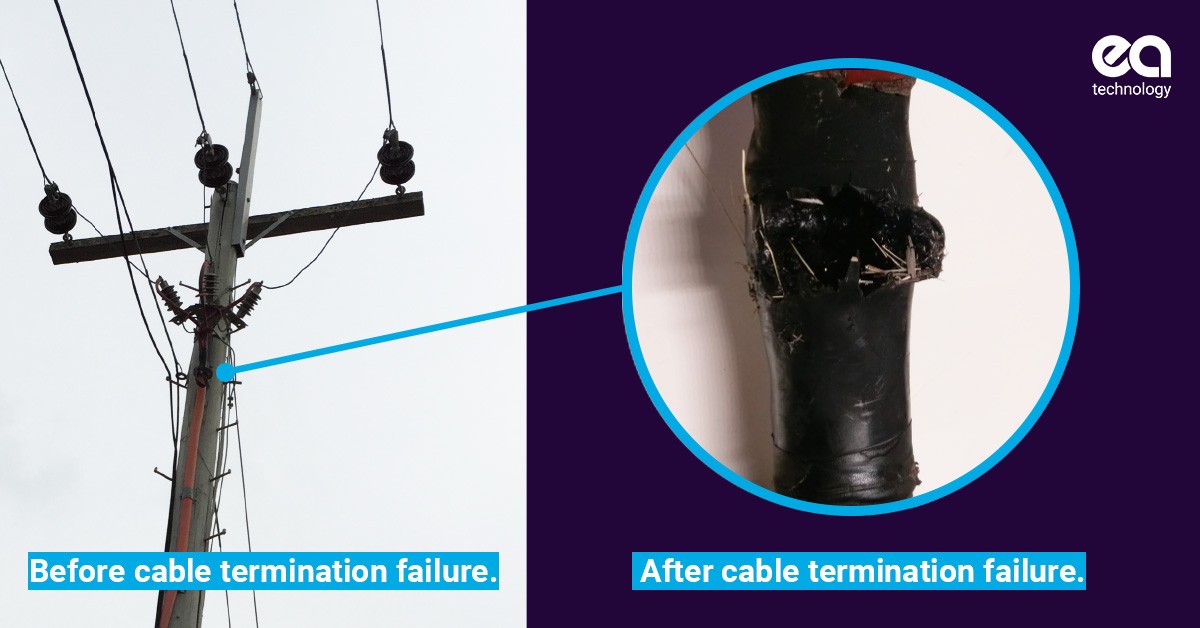

In this case study, I will give an example of a discharging defect that was picked up during a recent partial discharge (PD) survey. Unfortunately, the high voltage (HV) asset failed during service before it could be investigated further.

A PD survey was conducted at a mine site that relies on their above ground 11kV assets to feed all underground mining equipment and essentials. The HV cables that run from power poles on the surface to underground switchboards can be up to a few hundred metres long – these cables are critical to the company’s operations and safety. Discharge was detected toward the cable head termination of one of these HV cables.

Detection and Diagnosis

TEV: At the base of the pole (pictured) on the outside of the 11kV cable, a Transient Earth Voltage (TEV) test took place. TEV levels of 40dBmV with 1 pulse per cycle were detected: this amplitude and pulse count indicates high level, internal void type PD activity in the area.

TEV time-of-flight: The TEV time-of-flight test technique was then used, again at the base of the pole to determine the direction towards these TEV signals. Results indicated that the TEV signals were originating from the top of the pole.

Ultrasonic: The ultrasonic parabolic dish was then used to scan assets at the top of the pole for ultrasonic activity. Surface discharge activity was pinpointed to the HV cable termination area of the cable head termination.

Visual: The only abnormality that could visually be seen from the ground was the close proximity of phase cables at the termination.

Conclusion

Concluding from these tests, it was likely that an internal void discharging defect was located within the cable head termination and that surface PD activity was also present on the outside of the termination.

The most likely cause of an internal void defect would be workmanship during installation.

The surface PD was likely due to the red, white or blue phase cables being in close proximity to each other or contamination on the outside of the termination caused by airborne particles.

Recommendation

The recommendation following this was to shut down the cable, confirm the PD source and carry out remedial works. For an internal void discharge the only realistic course of action is to re-terminate.

Outcome

Due to the difficulty in organising an outage for this critical cable, the Engineering team were only able to arrange a shutdown to take place six months after testing. Unfortunately, after five months the cable termination disruptively failed whilst in service, shutting down parts of the operations on site. Investigation of the cable termination found that the failure took place at the crutch of the cable where the three phases separate (pictured) which is consistent with the detection of internal void PD activity.

Although regrettable that the failure occurred before the shutdown could take place, prior knowledge of the defect had at least enabled the company to get prepared and in a position so that supplies could be restored relatively quickly and downtime kept to a minimum.

This example makes for a good case study of how periodically conducting PD surveys on your HV assets is a worthwhile exercise, delivering real tangible value.