Partial Discharge Testing of Cables

-

12 June 2023

-

Jorge Rivera

Partial discharge testing of cables can be online or offline for medium to high voltage power cables. Cable PD occurs from a small insulation defect. It causes a discharge across part, but not all, of the insulation between conductors. The purpose of partial discharge testing of MV/HV cables is to find the discharge before it leads to flashover and catastrophic failure. Once PD starts, it will always grow until the insulation fails. This FAQ discusses testing of cables such as XLPE, EPR and PILC.

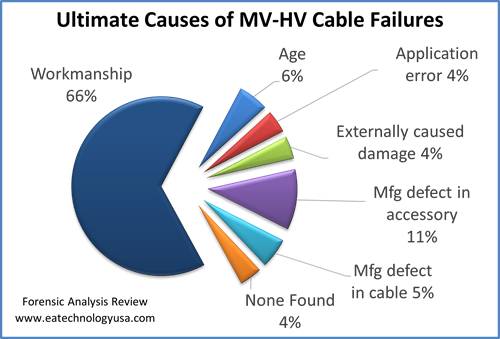

But what are the ultimate causes of medium to high voltage power cable failures? We performed a review of failed cables sent to the EA Technology Forensics Lab looking for patterns. Cable failures in a 5 year period were reviewed and the analysis published in NETA World.

Figure 1 below is an excerpt

Figure 1: Forensic Analysis Review of 70+ MV-HV cable failures over 5 yrs by EA Technology

Download a complete copy of the NETA World article here: Cable Failures.

With 2/3 as workmanship failures, it’s worth looking at further. Examples of field workmanship issues:

-Cutback errors in terminations.

-Contaminants getting into terminations. Remember, field work is performed outside, unlike the controlled environment of a cable manufacturer.

-Gaps and voids in insulation during terminations can be caused by common mistakes.

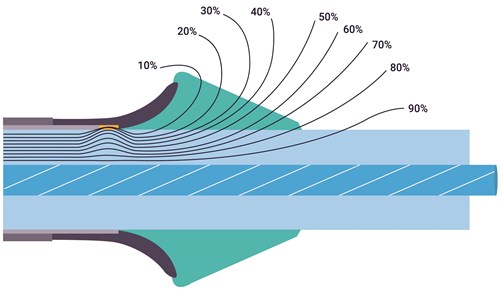

Power cable terminations are designed so voltage stresses won’t exceed the insulation capability at any point. They do this by ensuring the voltage gradients across the insulation are even. The figure below shows how the electrical stress is greater in and around the void.

Figure 2: Poor MV/HV cable termination creating voltage gradients that lead to PD

Cable termination procedures are very precisely engineered and any failure to follow them closely can lead to voids, field concentration, and then partial discharge.

Examples of application errors:

-Not following factory recommendations on mastic and other material choices.

-Insufficient shrinkage of heat shrink layers.

-Physical placement to adjacent cable.

Learn more about preventing cable termination failures in the first place with the slide deck of MV Cable Termination Failure Prevention presentation at the POWERTEST Conference: Download here

The next component of prevention is testing and monitoring for signs of deterioration. Most failures don’t happen by surprise… they can be predicted from early warning signs, most notably partial discharge testing.

Online vs Offline Partial Discharge Testing of Cables

Tan delta is a well known offline cable test. Tan delta tests the average cable insulation health along its length. Offline partial discharge testing is often done at the same time as tan delta. Offline cable PD testing provides more information but like tan delta requires isolation from equipment and a similar large test setup, which is more costly and time consuming than online PD cable testing.

Here is a comparison chart below of offline vs online PD cable testing.

|

CRITERIA |

OFFLINE PARTIAL DISCHARGE |

ONLINE PARTIAL DISCHARGE |

| Outage required? | Yes | No |

| Cost of test equipment | High | Medium |

| Skill required to run test | High | Low |

| Time per test | Long (>2 hours) | Short (<10 minutes) |

| TEST QUALITIES |

||

| Partial discharge presence | Yes | Yes |

| Partials discharge severity | Yes | Yes |

| Partial discharge location | Yes | Sometimes |

| Inception / extinction voltage | Yes | No |

Figure 3: Offline vs Online PD Testing Comparison Table

The above table is an excerpt from our NETA World article. Read the full article Online versus Offline Partial Discharge Testing for Cable Assessment for a more thorough comparison of tan delta, offline and online partial discharge testing.

Best practice is using online PD testing as a screening method as part of a condition based monitoring program. Survey large numbers of electrical assets quickly and at low cost to identify assets for further study. Now let’s discuss online cable PD testing in more detail.

Non-Intrusive Online Cable Partial Discharge Testing

Once a PD event has occurred through the electrical insulation of a cable, a set of radio frequency current pulses both equal in magnitude but opposite in polarity are seen on the line conductors and the earth conductor. In addition, if a PD event occurs between two phases, the effect of equal magnitude and opposite polarity is seen on the phase conductors that the PD event occurred. Online PD detection utilizes this effect by measuring these pulses using High Frequency Current Transformers (HFCTs) or Radio Frequency Current Transformers (RFCTs) placed on the earth sheath of the cable. The signals are of very high frequency (up to several hundred megahertz) and very small magnitude (perhaps only a few volts at most but more commonly in the millivolt range).

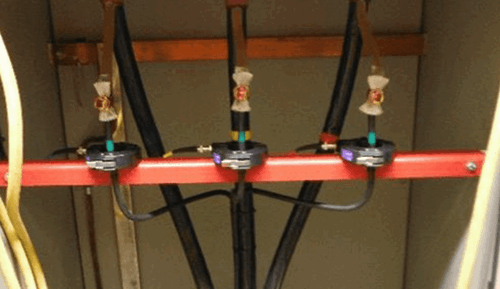

Figure 4: Online Cable PD Testing using the cable ground strap

Current through ground strap results from PD down cable. An entire length of cable can be tested from one end.

Figure 5: RFCT/HFCTs Installed in the field on each phase

Cable PD testing can be performed on live, energized, cables. The RFCT/HFCT can be installed on live cable ground straps with the appropriate PPE clothing and precautions. There are other alternatives:

-Install the RFCT/HFCT during an outage/shutdown.

-Once installed, leave the RFCT/HFCT in place for future periodic or even fulltime online monitoring.

-Use our specially designed RFCT Hotstick. The RFCT Hotstick is designed for temporarily RFCT installation on live cable grounds while maintaining a safe distance. The shotgun action allows the user to open and close the RFCT from the far end of the stick. This allow a user to be distanced from the cable ground connection when applying the RFCT. Careful use of the RFCT Hotstick can allow the user to reduce, but not eliminate, the shock and arc flash risk.

Figure 6: EA Technology RFCT Hotstick. Combines RFCT with standard 4-foot shotgun hotstick

*There are installation considerations beyond the scope of this article. Contact our office for a personal consultation.

EA Technology Cable PD Testing Solutions

In addition to the above mentioned RFCT Hotstick, EA Technology offers several solutions based on over 40 years of experience in dealing with partial discharge causes, effects, and detection methods.

|

UltraTEV Plus 2 is a portable instrument for cable PD testing and is also capable of testing for PD in cables, switchgear, substations, and more with ultrasonic, TEV, and UHF sensors for a complete powerful system. |

|

CableData Collector is a portable instrument for cable PD testing of up to three cables or phases simultaneously. Data samples are easily taken on site by your staff and analyzed by EA Technology using our expert systems. |

|

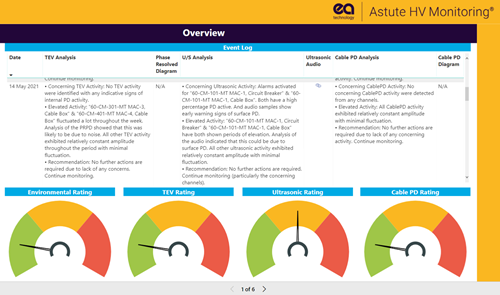

Astute HV Monitoring and CableData Monitor are fulltime online monitoring services for cables and/or switchgear. It is an advanced modular asset monitoring system for 24/7 monitoring of PD activity. It offers permanent monitoring and expertise to inform and recommend any actions. |

|

Power System Reliability Services such as power system consulting services, forensic failure investigation laboratory services, and electrical infrastructure audits. |

Additional Reading on Partial Discharge

Read our NETA World article Partial Discharge Secrets, Tips, and Tricks for answers to these frequently asked questions:

-Is it better for PD testing if the cable is grounded at one end or both?

-Is there a standard for acceptable PD levels in cables?

-Can you find PD inside the switchgear by testing the cable?

-How soon after energizing can you see PD?

Read our NETA World article ON-LINE CABLE PD TESTING with further discussion on theory, practical issues, limitations, and three case studies.

Watch our Recorded Webinars below:

Failure Prevention Through Effective Cable Monitoring

Medium Voltage Cable Failures - Rot Causes and Online Detection

Talk to an Expert

Thank you for your interest in EA Technology. You can request information or a free callback by clicking the link below. One of our experts will be in touch with you shortly.