Forensic Investigation Turns Up Major Systemic Concern

-

06 October 2023

-

EA Technology

Background

EA Technology was recently engaged by a large educational establishment to do a forensic investigation of a midspan failure of a medium voltage cable. The results were surprising and had far-reaching implications for the asset owner.

Forensic cable investigations are often done to determine whether the root cause of a failure is isolated or systemic. This helps the owner determine what risk exists in other assets and what actions should be taken to mitigate those risks.

Isolated random failures can be caused by conditions unlikely to be experienced by the remaining assets, thereby representing a minimal risk. An example of an isolated failure could be a termination caused by poor workmanship, done by a crew that was under-trained but did only the one termination.

Systemic failures that are caused by conditions common to multiple assets and represent a higher risk of future failures. An example of a systemic failure would be the same crew as described above that did all the terminations in a facility. This might require a larger mitigating action.

Our Approach

EA Technology stripped the cable down and determined that the failure was a conductor to shield flashover that was not caused by external influences. We sectioned slices of the insulation adjacent to the failure and some distance from the failure.

Sections from unfailed phases were also examined. See image 2.

We processed the samples of insulation so that internal details would be visible. High-power microscopic investigations were performed.

Large quantities of contaminants were present as seen in image 3.

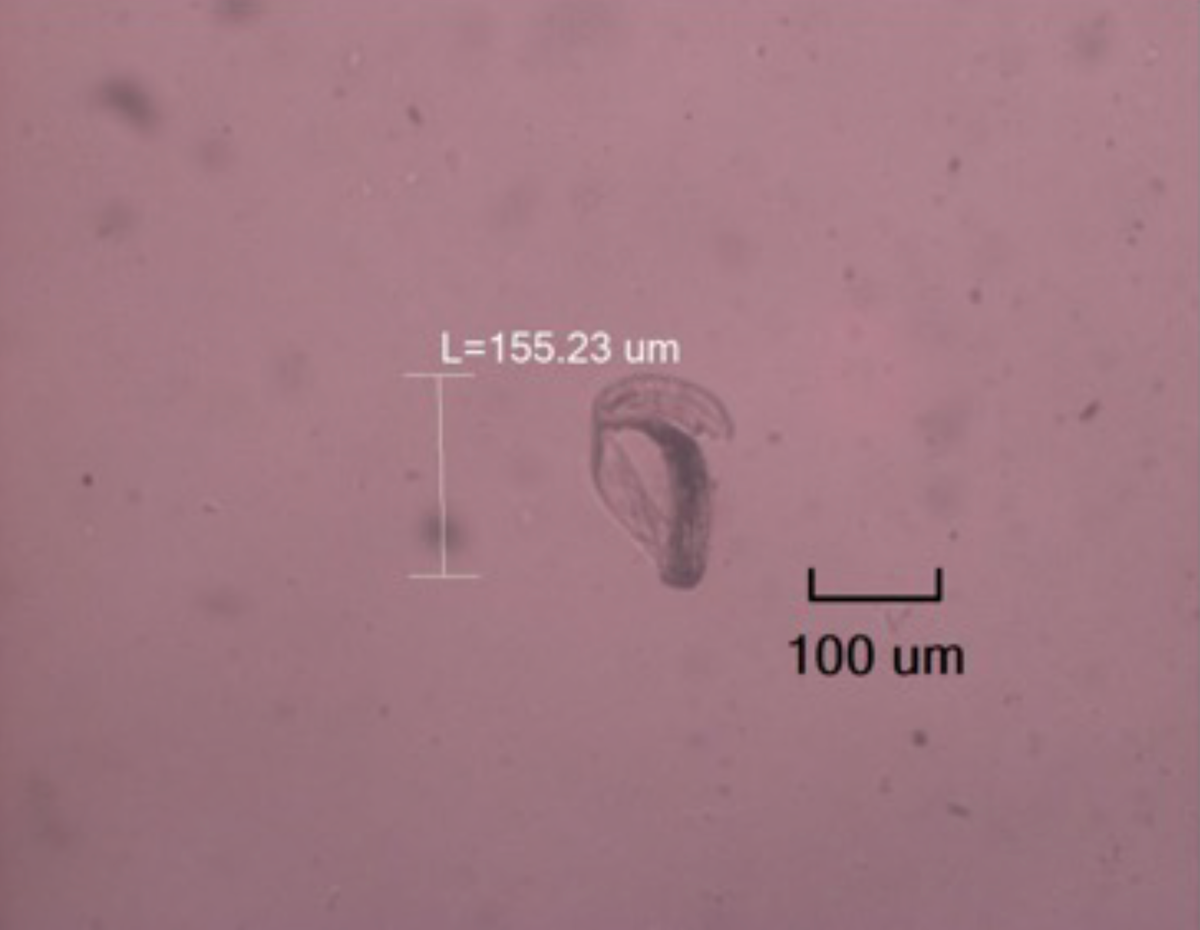

In addition to the one large defect, you can see spots of contamination throughout the insulation. These contaminants have been in the cable since its manufacture in 1968. Contaminants larger than 20 um are cause for concern and the high density of these large contaminants exacerbates the issue.

These contaminants cause uneven distribution of electrical stresses and lead to electrical trees. Large bowtie electrical trees are shown in image 4.

These electrical trees inevitably lead to failure. The size and quantity of these features make this cable unfit for continued operation.

Conclusion

This cable is quite old and has surpassed its design life. It should be replaced as soon as practical. Other cables in the same installation from the same manufacturer should be investigated to see if they too suffer from this contamination. It is possible that any cable in similar condition could fail at any time. In a perfect world, the operator would remove and replace all similar cables as a matter of priority.

Unfortunately, it’s not economically or practically feasible to replace all the affected cables. Fortunately, there are other steps the asset owners can take now that they are armed with this knowledge. Foremost, they should ensure that no offline testing at above line voltage, such as VLF withstand or tan/delta testing, is performed. Further, the operator can try to reduce any unnecessary switching that might cause transients. As a last line of defense, the operator can be prepared with replacement cable, terminations, splices, and trained field crews to react to any future failures.

The value in performing forensic investigations in cases like this is to be able to plan and take actions commensurate with the risks. The owner now knows the cables need to be replaced and can justify the cost with hard facts as opposed to estimated cable life spans.

Contact us to find out how we can help you with your failure investigations.