CableData® Monitor safeguards critical power supplies at INEOS Grangemouth

-

19 June 2024

-

EA Technology

INEOS is one of the largest chemical companies in the world, with an annual revenue in excess of $85bn. About a quarter of its revenue comes from fuels and lubricants, but it also has a large stake in packaging, food and construction, among other sectors. About 12% of its revenue is earned in the UK, mainly at its Grangemouth refinery and associated operations. It is also investing heavily in renewable energy

Background

Drive past the vast INEOS petrochemical plants in Grangemouth and you can’t help but be impressed by the scale, ambition, commitment and investment in this key piece of UK infrastructure. Critical to the operation is one of Europe’s largest private electricity distribution networks. At its heart is its gas-powered CHP plant that supplies electricity through two kilometre-long XLPE cable circuits.

During routine off-line VLF testing, EA Technology detected partial discharge (PD) occurring, at 3 joint positions along the cable route. This set alarm bells ringing. Had this PD activity degraded into complete failures, the potential for damage, repair cost and loss of revenue could have been immense.

INEOS turned to EA Technology to locate and monitor the PD online, thereby ascertaining the urgency and scope of the PD, and therefore the need for shutdowns and remedial work.

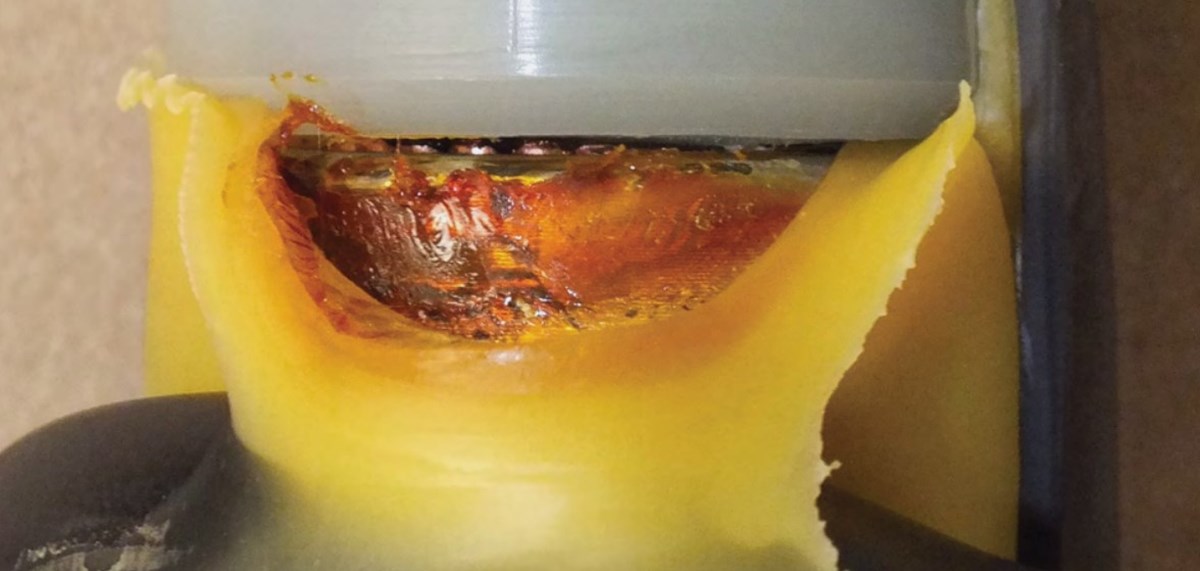

One of the three HV cables at the Grangemouth site where routine testing revealed critical PD activity.

Actions

With EA Technology’s advice, INEOS recognised that they needed to be more proactive and precise in monitoring PD. After assessing the scale of the problem, we implemented our Astute HV Monitoring® system that analyses the condition of critical cables using permanently installed radio frequency current transformers (RFCTs).

The system confirmed the initial finding of partial discharge, and pinpointed three locations where suspect joint-pairs were located. Because of the way Astute works, the testing was carried out while the cable circuits were live, meaning the plant could continue working at full capacity, and any remedial work could be scheduled during routine shutdowns or, if more urgent, during low-demand periods.

As the assessment concluded that there was no imminent threat, the plant stayed fully operational for a further ten months before the relevant joints were replaced during a routine shutdown.

During the ten-month period, monitoring was continuous and the issue showed no critical degradation, so both parties were comfortable with staying online. Had severe deterioration or an increased frequency of PD been discovered, our advice might well have been to shut down.

The System

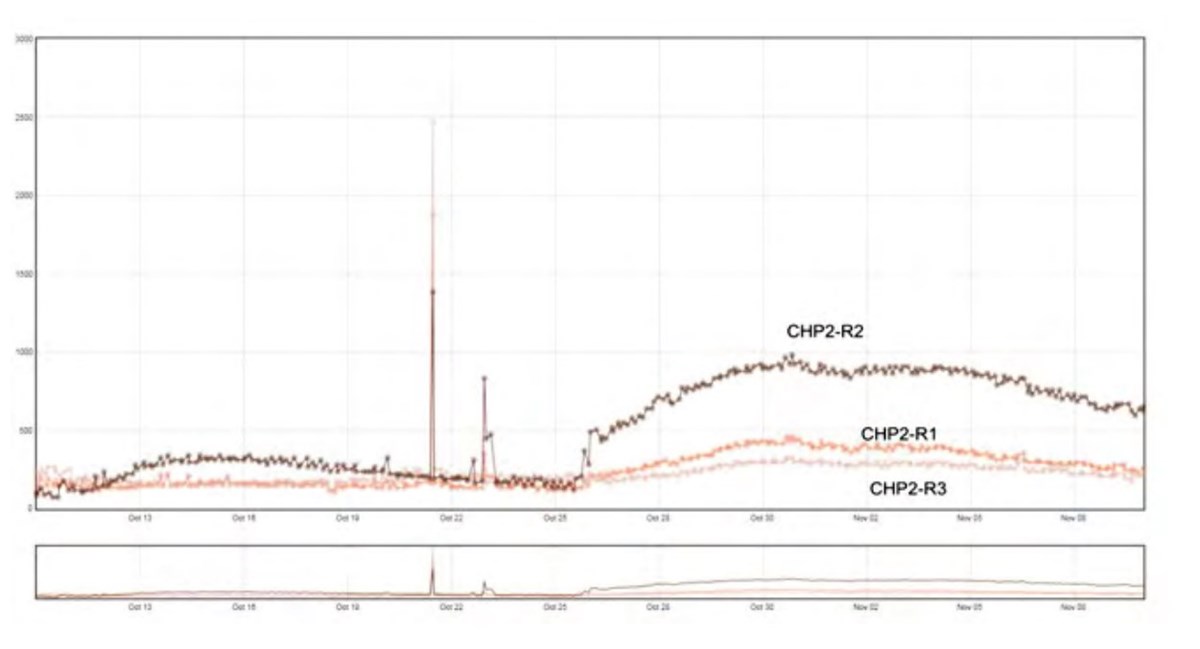

CableData Monitor® uses RFCTs to provide 24/7 conditional monitoring of cables. No extensive engineering is required during installation as the monitoring devices are simply clipped around the earth strap on the substation cable terminations. The advantage of continuous monitoring is that spikes that might not be detected in a random spot test will inevitably show up over time. The graph below shows an actual example – this time from our INEOS monitoring – of how partial discharges cannot go unnoticed.

Because the performance of customers’ cables is monitored remotely at EA Technology’s laboratories, monitoring is as unobtrusive as possible.

EA Technology aims to confidently enable customers to have 99.999% availability of their HV assets. The ability to forecast failures means that remedial action can be performed intelligently, in the sweet spot between costly overcautious shutdowns and fingers-crossed complacency

Conclusion

The deployment of EA Technology’s CableData Monitor® and Astute HV Monitoring® service at INEOS’ Grangemouth complex is a clear demonstration of the wisdom of a ‘fix before fail’ approach to asset management.

Failure of any of the cable joints in their primary substation could have resulted in a catastrophic loss of production, costing £millions to the company and the UK economy. The solution INEOS has chosen not only helps prevent unplanned outages: it gives them the peace of mind that assets are working correctly, with the ability to plan maintenance intelligently.

The bottom line is that the cost of continuous monitoring would be massively outweighed by the cost of even a short production hiccup